Introduction

In

early 1900s, Gas chromatography (GC) was discovered by Mikhail

Semenovich Tsvett as a separation technique to separate compounds. In

organic chemistry, liquid-solid column chromatography is often used to

separate organic compounds in solution. Among the various types of gas

chromatography, gas-liquid chromatography is the method most commonly

used to separate organic compounds. The combination of gas

chromatography and mass spectrometry is an invaluable tool in the

identification of molecules. A typical gas chromatograph consists of an

injection port, a column, carrier gas flow control equipment, ovens and

heaters for maintaining temperatures of the injection port and the

column, an integrator chart recorder and a detector.

To

separate the compounds in gas-liquid chromatography, a solution sample

that contains organic compounds of interest is injected into the sample

port where it will be vaporized. The vaporized samples that are injected

are then carried by an inert gas, which is often used by helium or

nitrogen. This inert gas goes through a glass column packed with silica

that is coated with a liquid. Materials that are less soluble in the

liquid will increase the result faster than the material with greater

solubility.The purpose of this module is to provide a better

understanding on its separation and measurement techniques and its

application.

In GLC, the liquid

stationary phase is adsorbed onto a solid inert packing or immobilized

on the capillary tubing walls. The column is considered packed if the

glass or metal column tubing is packed with small spherical inert

supports. The liquid phase adsorbs onto the surface of these beads in a

thin layer. In a capillary column, the tubing walls are coated with

the stationary phase or an adsorbant layer, which is capable of

supporting the liquid phase. However, the method of GSC, has limited

application in the laboratory and is rarely used due to severe peak

tailing and the semi-permanent retention of polar compounds within the

column. Therefore, the method of gas-liquid chromatography is simply

shortened to gas chromatography and will be referred to as such here.The

purpose of this module is to provide a better understanding on its

separation and measurement techniques and its application.

Instrumentation

Sample Injection

A sample port is necessary for

introducing the sample at the head of the column. Modern injection

techniques often employ the use of heated sample ports through which the

sample can be injected and vaporized in a near simultaneous fashion. A

calibrated microsyringe is used to deliver a sample volume in the range

of a few microliters through a rubber septum and into the vaporization

chamber. Most separations require only a small fraction of the initial

sample volume and a sample splitter is used to direct excess sample to

waste. Commercial gas chromatographs often allow for both split and

splitless injections when alternating between packed columns and

capillary columns. The vaporization chamber is typically heated 50 °C

above the lowest boiling point of the sample and subsequently mixed with

the carrier gas to transport the sample into the column.

Figure 1. A cross-sectional view of a microflash vaporizer direct injector.

Carrier Gas

The carrier gas plays an important

role, and varies in the GC used. Carrier gas must be dry, free of oxygen

and chemically inert mobile-phase employed in gas chromatography.

Helium is most commonly used because it is safer than, but comprable to

hydrogen in efficiency, has a larger range of flow rates and is

compatable with many detectors. Nitrogen, argon, and hydrogen are also

used depending upon the desired performance and the detector being

used. Both hydrogen and helium, which are commonly used on most

traditional detectors such as Flame Ionization(FID), thermal

conductivity (TCD) and Electron capture (ECD), provide a shorter

analysis time and lower elution temperatures of the sample due to higher

flow rates and low molecular weight. For instance, hydrogen or helium

as the carrier gas gives the highest sensitivity with TCD because the

difference in thermal conductivity between the organic vapor and

hydrogen/helium is greater than other carrier gas. Other detectors such

as mass spectroscopy, uses nitrogen or argon which has a much better

advantage than hydrogen or helium due to their higher molecular weights,

in which improve vacuum pump efficiency.

All carrier gasses are available in

pressurized tanks and pressure regulators, gauges and flow meters are

used to meticulously control the flow rate of the gas. Most gas supplies

used should fall between 99.995% - 99.9995% purity range and contain a

low levels (< 0.5 ppm) of oxygen and total hydrocarbons in the tank.

The carrier gas system contains a molecular sieve to remove water and

other impurities. Traps are another option to keep the system pure and

optimum sensitive and removal traces of water and other contaminants. A

two stage pressure regulation is required to use to minimize the

pressure surges and to monitor the flow rate of the gas. To monitor the

flow rate of the gas a flow or pressure regulator was also require onto

both tank and chromatograph gas inlet. This applies different gas type

will use different type of regulator.The carrier gas is preheated and

filtered with a molecular sieve to remove impurities and water prior to

being introduced to the vaporization chamber. A carrier gas is typically

required in GC system to flow through the injector and push the gaseous

components of the sample onto the GC column, which leads to the

detector ( see more detail in detector section).

Figure 2. Gas

Recommendations for Capillary

Columns Figure 3. Gas

Recommendations for Packed Columns

Column Oven

The thermostatted oven serves to control

the temperature of the column within a few tenths of a degree to

conduct precise work. The oven can be operated in two

manners: isothermal programming or temperature programming. In

isothermal programming, the temperature of the column is held constant

throughout the entire separation. The optimum column temperature for

isothermal operation is about the middle point of the boiling range of

the sample. However, isothermal programming works best only if the

boiling point range of the sample is narrow. If a low isothermal column

temperature is used with a wide boiling point range, the low boiling

fractions are well resolved but the high boiling fractions are slow to

elute with extensive band broadening. If the temperature is increased

closer to the boiling points of the higher boiling components, the

higher boiling components elute as sharp peaks but the lower boiling

components elute so quickly there is no separation.

In the temperature programming method,

the column temperature is either increased continuously or in steps as

the separation progresses. This method is well suited to separating a

mixture with a broad boiling point range. The analysis begins at a low

temperature to resolve the low boiling components and increases during

the separation to resolve the less volatile, high boiling components of

the sample. Rates of 5-7 °C/minute are typical for temperature

programming separations.

Figure 3. The effect of column temperature on the shape of the peaks.

Open Tubular Columns and Packed Columns

Open tubular columns, which are also

known as capillary columns, come in two basic forms. The first is a

wall-coated open tubular (WCOT) column and the second type is a

support-coated open tubular (SCOT) column. WCOT columns are capillary

tubes that have a thin later of the stationary phase coated along the

column walls. In SCOT columns, the column walls are first coated with a

thin layer (about 30 micrometers thick) of adsorbant solid, such as

diatomaceous earth, a material which consists of single-celled,

sea-plant skeletons. The adsorbant solid is then treated with the

liquid stationary phase. While SCOT columns are capable of holding a

greater volume of stationary phase than a WCOT column due to its greater

sample capacity, WCOT columns still have greater column efficiencies.

Most modern WCOT columns are made of

glass, but T316 stainless steel, aluminum, copper and plastics have also

been used. Each material has its own relative merits depending upon

the application. Glass WCOT columns have the distinct advantage of

chemical etching, which is usually achieved by gaseous or concentrated

hydrochloric acid treatment. The etching process gives the glass a

rough surface and allows the bonded stationary phase to adhere more

tightly to the column surface.

One of the most popular types of

capillary columns is a special WCOT column called the fused-silica

wall-coated (FSWC) open tubular column. The walls of the fused-silica

columns are drawn from purified silica containing minimal metal oxides.

These columns are much thinner than glass columns, with diameters as

small as 0.1 mm and lengths as long as 100 m. To protect the column, a

polyimide coating is applied to the outside of the tubing and bent into

coils to fit inside the thermostatted oven of the gas chromatography

unit. The FSWC columns are commercially available and currently

replacing older columns due to increased chemical inertness, greater

column efficiency and smaller sampling size requirements. It is

possible to achieve up to 400,000 theoretical plates with a 100 m WCOT

column, yet the world record for the largest number of theoretical

plates is over 2 million plates for 1.3 km section of column.

Packed columns are made of a glass or a

metal tubing which is densely packed with a solid support like

diatomaceous earth. Due to the difficulty of packing the tubing

uniformly, these types of columns have a larger diameter than open

tubular columns and have a limited range of length. As a result, packed

columns can only achieve about 50% of the efficiency of a comparable

WCOT column. Furthermore, the diatomaceous earth packing is deactivated

over time due to the semi-permanent adsorption of impurities within the

column. In contrast, FSWC open tubular columns are manufactured to be

virtually free of these adsorption problems.

Figure 4. Properties of gas chromatography columns.

Figure 5. Computer Generated Image of a FSWC column (specialized for measuring BAC levels)

Figure 6. Computer Generated Image of a FSWC column (specialized to withstand extreme heat)

Different types of columns can be

applied for different fields. Depending on the type of sample, some GC

columns are better than the others. For example, the FSWC column shown

in Figure 5 is designed specially for blood alcohol analysis. It

produces fast run times with baseline resolution of key components in

under 3 minutes. Moreover, it displays enhanced resolutions of ethanol

and acetone peaks, which helps with determining the BAC levels. This

particular column is known as Zebron-BAC and it made with polyimide

coating on the outside and the inner layer is made of fused silica and

the inner diameter ranges from .18 mm to .25 mm. There are also many

other Zebron brand columns designed for other purposes.

Another example of a Zebron GC column is

known as the Zebron-inferno. Its outer layer is coated with a special

type of polyimide that is designed to withstand high temperatures. As

shown in figure 6, it contains an extra layer inside. It can withstand

up to 430 °C to be exact and it is designed to provide true boiling

point separation of hydrocarbons distillation methods. Moreover, it is

also used for acidic and basic samples.

Detection Systems

The detector is the device located at

the end of the column which provides a quantitative measurement of the

components of the mixture as they elute in combination with the carrier

gas. In theory, any property of the gaseous mixture that is different

from the carrier gas can be used as a detection method. These detection

properties fall into two categories: bulk properties and specific

properties. Bulk properties, which are also known as general

properties, are properties that both the carrier gas and analyte possess

but to different degrees. Specific properties, such as detectors that

measure nitrogen-phosphorous content, have limited applications

but compensate for this by their increased sensitivity.

Each detector has two main parts that

when used together they serve as transducers to convert the detected

property changes into an electrical signal that is recorded as a

chromatogram. The first part of the detector is the sensor which is

placed as close the the column exit as possible in order to optimize

detection. The second is the electronic equipment used to digitize the

analog signal so that a computer may analyze the acquired chromatogram.

The sooner the analog signal is converted into a digital signal, the

greater the signal-to-noise ratio becomes, as analog signal are easily

susceptible to many types of interferences.

An ideal GC detector is distinguished by

several characteristics. The first requirement is adequate sensitivity

to provide a high resolution signal for all components in the mixture.

This is clearly an idealized statement as such a sample would approach

zero volume and the detector would need infinite sensitivity to detect

it. In modern instruments, the sensitivities of the detectors are in

the range of 10-8 to 10-15 g of solute per

second. Furthermore, the quantity of sample must be reproducible and

many columns will distort peaks if enough sample is not injected. An

ideal column will also be chemically inert and and should not alter the

sample in any way. Optimized columns will be able to withstand

temperatures in the range of -200 °C to at least 400 °C. In addition,

such a column would have a short linear response time that is

independent of flow rate and extends for several orders of magnitude.

Moreover, the detector should be reliable, predictable and easy to

operate.

Understandably, it is not possible for a

detector meet all of these requirements. The next subsections will

discuss some of the more common types of gas chromatography detectors

and the relative advantages and/or disadvantages of each.

|

Type of Detector

|

Applicable Samples

|

Detection Limit

|

|

Mass Spectrometer (MS)

|

Tunable for any sample

|

.25 to 100 pg

|

|

Flame Ionization (FID)

|

Hydrocarbons

|

1 pg/s

|

|

Thermal Conductivity (TCD)

|

Universal

|

500 pg/ml

|

|

Electron-Capture (ECD)

|

Halogenated hydrocarbons

|

5 fg/s

|

|

Atomic Emission (AED)

|

Element-selective

|

1 pg

|

|

Chemiluminescence (CS)

|

Oxidizing reagent

|

Dark current of PMT

|

|

Photoionization (PID)

|

Vapor and gaseous Compounds

|

.002 to .02 µg/L

|

Table 7: Typical gas chromatography detectors and their detection limits.

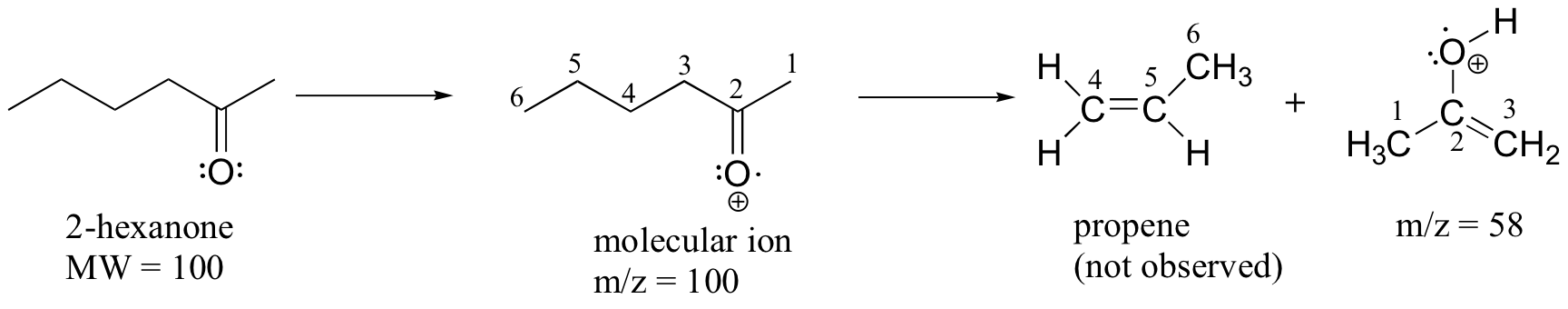

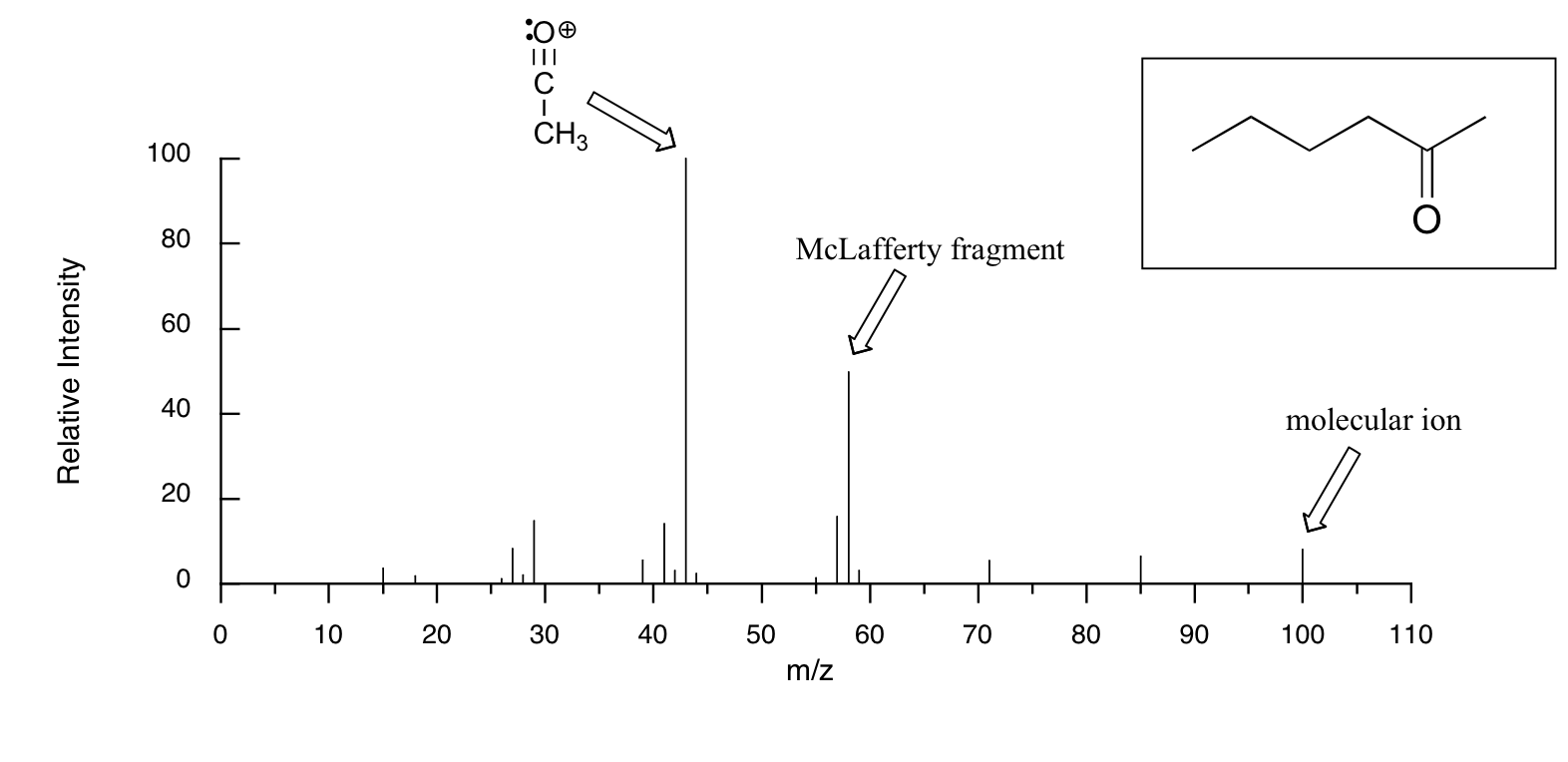

Mass Spectrometry Detectors

Mass Spectrometer (MS) detectors are most

powerful of all gas chromatography detectors. In a GC/MS system, the

mass spectrometer scans the masses continuously throughout the

separation. When the sample exits the chromatography column, it

is passed through a transfer line into the inlet of the mass

spectrometer . The sample is then ionized and fragmented, typically by

an electron-impact ion source. During this process, the sample is

bombarded by energetic electrons which ionize the molecule by causing

them to lose an electron due to electrostatic repulsion. Further

bombardment causes the ions to fragment. The ions are then passed into a

mass analyzer where the ions are sorted according to their m/z value,

or mass-to-charge ratio. Most ions are only singly charged.

The Chromatogram will point out the

retention times and the mass spectrometer will use the peaks to

determine what kind of molecules are exist in the mixture. The figure

below represents a typical mass spectrum of water with the absorption

peaks at the appropriate m/z ratios.

Figure 8. Mass Spectrum of Water

Instrumentation

One of the most common types of mass

analyzer in GC/MS is the quadrupole ion-trap analyzer, which allows

gaseous anions or cations to be held for long periods of time by

electric and magnetic fields. A simple quadrupole ion-trap consists of a

hollow ring electrode with two grounded end-cap electrodes as seen in

figure #. Ions are allowed into the cavity through a grid in the upper

end cap. A variable radio-frequency is applied to the ring electrode and

ions with an appropriate m/z value orbit around the cavity. As the

radio-frequency is increased linearly, ions of a stable m/z value are

ejected by mass-selective ejection in order of mass. Ions that are too

heavy or too light are destabilized and their charge is neutralized upon

collision with the ring electrode wall. Emitted ions then strike an

electron multiplier which converts the detected ions into an electrical

signal. This electrical signal is then picked up by the computer through

various programs. As an end result, a chromatogram is produced

representing the m/z ratio versus the abundance of the sample.

GC/MS units are advantageous because

they allow for the immediate determination of the mass of the analyte

and can be used to identify the components of incomplete separations.

They are rugged, easy to use and can analyze the sample almost as

quickly as it is eluted. The disadvantages of mass spectrometry

detectors are the tendency for samples to thermally degrade before

detection and the end result of obliterating all the sample by

fragmentation.

Figure 9. Schematic of the GC/MS system.

Figure 10. Arrangement of the poles in Quadrupole and Ion Trap Mass spectrometers

Flame Ionization Detectors

Flame ionization detectors (FID) are the

most generally applicable and most widely used detectors. In a FID, the

sample is directed at an air-hydrogen flame after exiting the column.

At the high temperature of the air-hydrogen flame, the sample undergoes

pyrolysis, or chemical decomposition through intense heating. Pyrolized

hydrocarbons release ions and electrons that carry current. A

high-impedance picoammeter measures this current to monitor the sample's

elution.

It is advantageous to used FID because

the detector is unaffected by flow rate, noncombustible gases and

water. These properties allow FID high sensitivity and low noise. The

unit is both reliable and relatively easy to use. However, this

technique does require flammable gas and also destroys the sample.

Figure 11. Schematic of a typical flame ionization detector.

Thermal Conductivity Detectors

Thermal conductivity detectors (TCD) were

one the earliest detectors developed for use with gas chromatography.

The TCD works by measuring the change in carrier gas thermal

conductivity caused by the presence of the sample, which has a different

thermal conductivity from that of the carrier gas. Their design is

relatively simple, and consists of an electrically heated source that is

maintained at constant power. The temperature of the source depends

upon the thermal conductivities of the surrounding gases. The source is

usually a thin wire made of platinum, gold or . The resistance within

the wire depends upon temperature, which is dependent upon the thermal

conductivity of the gas.

TCDs usually employ two detectors, one of

which is used as the reference for the carrier gas and the other which

monitors the thermal conductivity of the carrier gas and sample

mixture. Carrier gases such as helium and hydrogen has very high

thermal conductivities so the addition of even a small amount of sample

is readily detected.

The advantages of TCDs are the ease and

simplicity of use, the devices' broad application to inorganic and

organic compounds, and the ability of the analyte to be collected after

separation and detection. The greatest drawback of the TCD is the low

sensitivity of the instrument in relation to other detection methods, in

addition to flow rate and concentration dependency.

Figure 12. Schematic of thermal conductivity detection cell.

Figure 13. Standard Chromatogram of a Mixture of Gases

Chromatogram

Figure 13 represents a standard

chromatogram produced by a TCD detector. In a standard chromatogram

regardless of the type detector, the x-axis is the time and the y-axis

is the abundance or the absorbance. From these chromatograms, retention

times and the peak heights are determined and used to further

investigate the chemical properties or the abundance of the samples.

Electron-capture Detectors

Electron-capture detectors (ECD) are

highly selective detectors commonly used for detecting environmental

samples as the device selectively detects organic compounds

with moieties such as halogens, peroxides, quinones and nitro groups and

gives little to no response for all other compounds. Therefore, this

method is best suited in applications where traces quantities of

chemicals such as pesticides are to be detected and other

chromatographic methods are unfeasible.

The simplest form of ECD involves gaseous

electrons from a radioactive ? emitter in an electric field. As the

analyte leaves the GC column, it is passed over this ? emitter, which

typically consists of nickle-63 or tritium. The electrons from the ?

emitter ionize the nitrogen carrier gas and cause it to release a burst

of electrons. In the absence of organic compounds, a constant standing

current is maintained between two electrodes. With the addition of

organic compounds with electronegative functional groups, the current

decreases significantly as the functional groups capture the

electrons.

The advantages of ECDs are the high

selectivity and sensitivity towards certain organic species with

electronegative functional groups. However, the detector has a limited

signal range and is potentially dangerous owing to its radioactivity.

In addition, the signal-to-noise ratio is limited by radioactive decay

and the presence of O2 within the detector.

Figure 14. Schematic of an electron-capture detector.

Atomic Emission Detectors

Atomic emission detectors (AED), one of

the newest addition to the gas chromatographer's arsenal, are

element-selective detectors that utilize plasma, which is a partially

ionized gas, to atomize all of the elements of a sample and excite their

characteristic atomic emission spectra. AED is an extremely powerful

alternative that has a wider applicability due to its based on the

detection of atomic emissions.There are three ways of generating plasma:

microwave-induced plasma (MIP), inductively coupled plasma (ICP) or

direct current plasma (DCP). MIP is the most commonly employed form and

is used with a positionable diode array to simultaneously monitor the

atomic emission spectra of several elements.

InstrumentationThe components of the Atomic emission detectors include 1) an interface for the incoming capillary GC column to induce plasma chamber,2) a microwave chamber, 3) a cooling system, 4) a diffration grating that associated optics, and 5) a position adjustable photodiode array interfaced to a computer.

Figure 15. Schematic of atomic emission detector.

GC Chemiluminescence Detectors

Chemiluminescence spectroscopy (CS) is a

process in which both qualitative and quantitative properties can be be

determined using the optical emission from excited chemical species. It

is very similar to AES, but the difference is that it utilizes the

light emitted from the energized molecules rather than just excited

molecules. Moreover, chemiluminescence can occur in either the solution

or gas phase whereas AES is designed for gaseous phases. The light

source for chemiluminescence comes from the reactions of the chemicals

such that it produces light energy as a product. This light band is used

instead of a separate source of light such as a light beam.

Like other methods, CS also has its limitations and the major

limitation to the detection limits of CS concerns with the use of a

photomultiplier tube (PMT). A PMT requires a dark current in it to

detect the light emitted from the analyte.

Figure 16. Schematic of a GC Chemiluminescence Detector

Photoionization Detectors

Another different kind of detector for

GC is the photoionization detector which utilizes the properties of

chemiluminescence spectroscopy. Photoionization detector (PID) is a

portable vapor and gas detector that has selective determination of

aromatic hydrocarbons, organo-heteroatom, inorganice species and other

organic compounds. PID comprise of an ultrviolet lamp to emit photons

that are absorbed by the compounds in an ionization chamber exiting from

a GC column. Small fraction of the analyte molecules are actually

ionized, nondestructive, allowing confirmation analytical results

through other detectors. In addition, PIDs are available in portable

hand-held models and in a number of lamp configurations. Results are

almost immediate. PID is used commonly to detect VOCs in soil, sediment,

air and water, which is often used to detect contaminants in ambient

air and soil. The disavantage of PID is unable to detect certain

hydrocarbon that has low molecular weight, such as methane and ethane.

Instrumentation

Figure 17. Schematic of a photoionization detector

Limitations

- Not suitable for detecting semi-volatile compounds

- Only indicates if volatile organic compounds are presents.

- High concentration so methane are required for higher performance.

- Frequent calibration are required.

- Units of parts per million range

- Enviromental distraction, especially water vapor.

- Strong electrical fieldsRapid variation in temperature at the detector and naturally occurring compounds may affect instrumental signal.

Applications

Gas chromatography is a physical

separation method in where volatile mixtures are separated. It can be

used in many different fields such as pharmaceuticals, cosmetics and

even environmental toxins. Since the samples have to be volatile, human

breathe, blood, saliva and other secretions containing large amounts of

organic volatiles can be easily analyzed using GC. Knowing the amount of

which compound is in a given sample gives a huge advantage in studying

the effects of human health and of the environment as well.

Air samples can be analyzed using GC.

Most of the time, air quality control units use GC coupled with FID in

order to determine the components of a given air sample. Although other

detectors are useful as well, FID is the most appropriate because of its

sensitivity and resolution and also because it can detect very small

molecules as well.

GC/MS is also another useful method

which can determine the components of a given mixture using the

retention times and the abundance of the samples. This method be applied

to many pharmaceutical applications such as identifying the amount of

chemicals in drugs. Moreover, cosmetic manufacturers also use this

method to effectively measure how much of each chemical is used for

their products.

Equations

“Height equivalent to a theoretical

plate” (HETP) use to calculate the flow rate by usingthe total number

of theoretical plates (N) and column length (L). Some application, HETP

concepts is used in industrial practice to convert number of theoretical

plates to packing height. HETP can be calculate with the Van Deemter

equation, which is given by

Where A and B and C are constants and v is the linear velocity (carrier flow rate).

- A is the "Eddy-Diffusion" term and causes the broadering of the solute band.

- B is the "Longitudinal diffusion" term whereby the concentration of the analyte, in which diffuses out from the center to the edges.This causes the broadering of the analyte band.

- C is the "Resistance to Mass Transfer " term and causes the band of the analyte broader.

L is the length of the column, where N

is the number of theoretical plates, tR is the retention time, and ω is

the width of the elution peak at its base.

In which, the more plates give a better resolution and more efficiency. Resolution can be determined by

R= 2[ (tR)B – (tR)A] / ( WA +WB) (4)

A relationship between the plates and resolution is giving by,

No comments:

Post a Comment